My name is Kelly Michals. I studied Mining Engineering at the Colorado School of Mines in Golden, Colorado. Growing up in Denver, I was always fascinated by science and engineering, which naturally led me to pursue that path at a university known for its excellence in those fields.

After graduating, I began my career with Sandvik, a global leader in the mining sector specializing in drilling and mobile crushing equipment. It was a formative experience—I traveled extensively, spent much of my time on the road, and eventually relocated to the Atlanta area. Those years taught me adaptability and gave me a deep appreciation for the fast-paced, hands-on side of mining operations.

Later, I transitioned to working directly at a mine as a mining engineer, which gave me valuable insight into day-to-day challenges from the customer’s perspective. When the opportunity arose to join ME Elecmetal, I was recruited by a former colleague who was already part of the team. Returning to the supplier side felt like the perfect fit—it allowed me to combine my technical background with my passion for helping operations succeed.

Outside of work, I love exploring new places. I’m a huge fan of U.S. National Parks—there are more than 400 across the country, and I’ve visited about 350 so far. Hiking is one of my favorite ways to unwind and connect with nature. My favorite park is Death Valley in California—it’s massive, larger than some states, and its landscapes are unbelievably diverse, from vast deserts and rugged mountains to volcanic craters and salt flats below sea level. I currently live alone in Tucson, Arizona, with my cat, who’s about to turn 12.

What attracted you to ME Elecmetal?

When ME Elecmetal reached out, I was working as a mining engineer at a single site. I enjoyed the work, but I was ready for a change—spending years in one place had started to feel limiting.

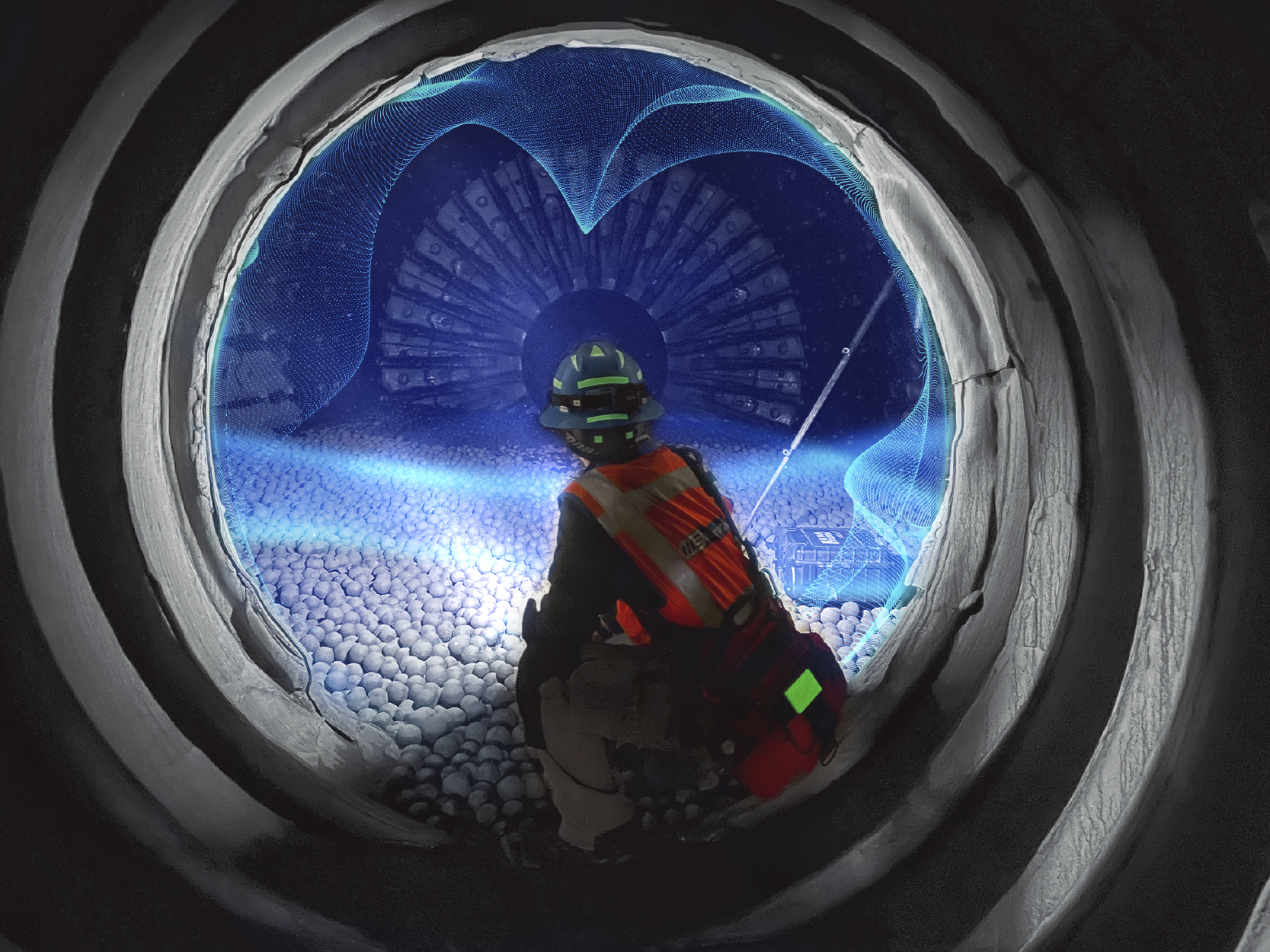

I joined ME Elecmetal as a field technician specializing in scanning, which put me back on the road and allowed me to visit a variety of mine sites across North America. That mobility reignited my passion for fieldwork and problem-solving. Over time, the role evolved to include new responsibilities, such as ferromagnetic scanning, and has since grown into a broader Field Engineering position. Today, our focus is on expanding the range of technical services we provide directly at customer operations—bringing solutions closer to the people who need them most.

I now travel extensively throughout the United States and Canada, and I’m based in Tucson, Arizona, which keeps me close to our Tempe, Arizona foundry and many of our customers in the region.

How would you describe the culture at ME Elecmetal?

In my experience, working in a mine can sometimes involve very strict hierarchies and limited communication, which can make the environment feel rigid and exhausting.

ME Elecmetal is the complete opposite: there is open dialogue between everyone, regardless of their role. Everyone can raise their hand, share ideas, and propose improvements. There is no perception of a rigid structure, but rather a team where everyone contributes.

There’s also a strong sense of community. We celebrate milestones together, organize events, share meals, and genuinely enjoy connecting with one another. It’s common to see both long-time employees and new hires participating side by side, and the atmosphere is consistently positive. There is a sense of belonging, where you feel listened to, valued, and part of the team.