Longer Service Life

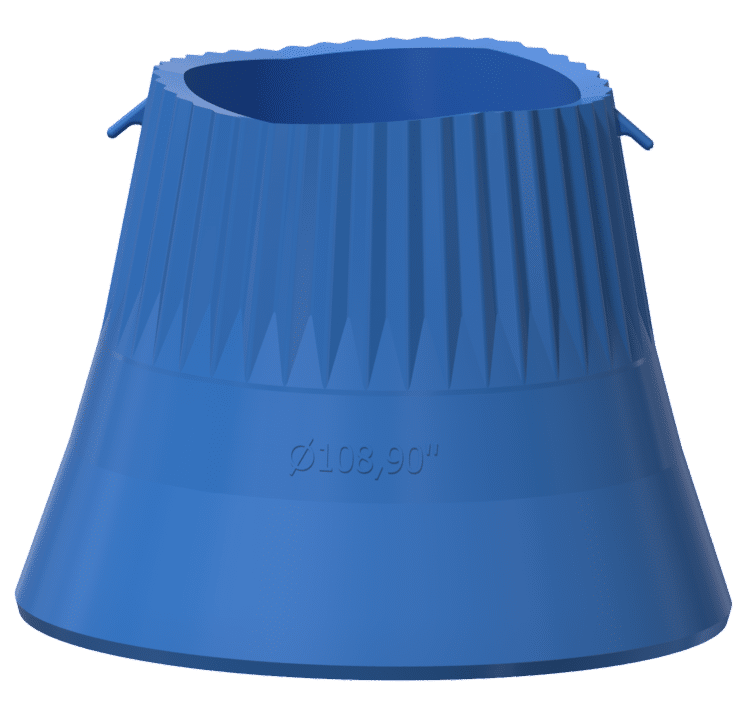

Because we use top-quality wear materials our products last longer, thereby extending the service life of each product.

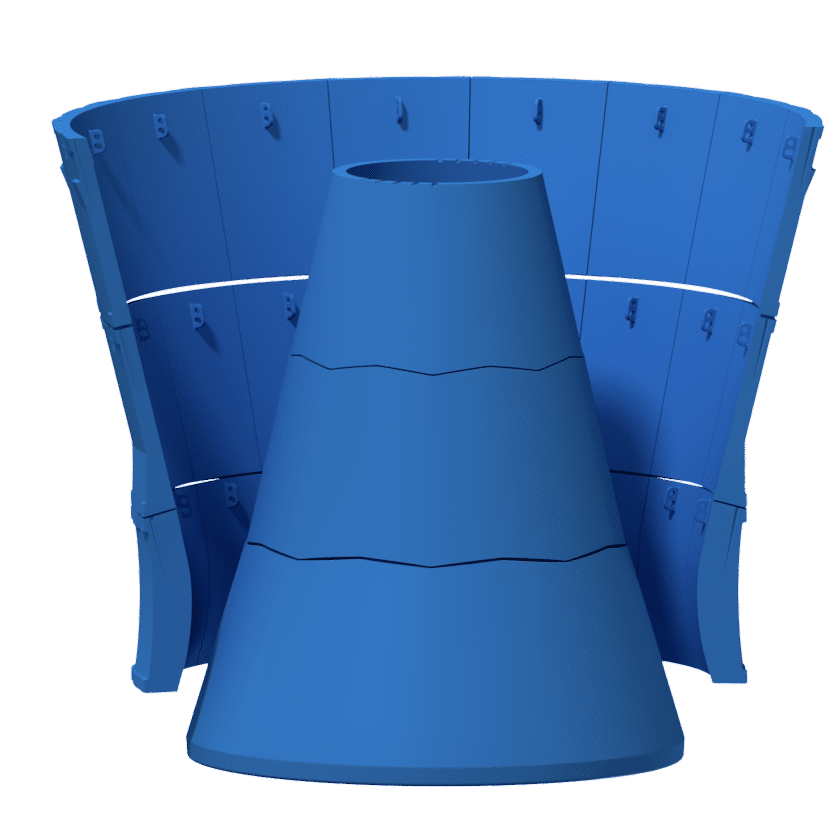

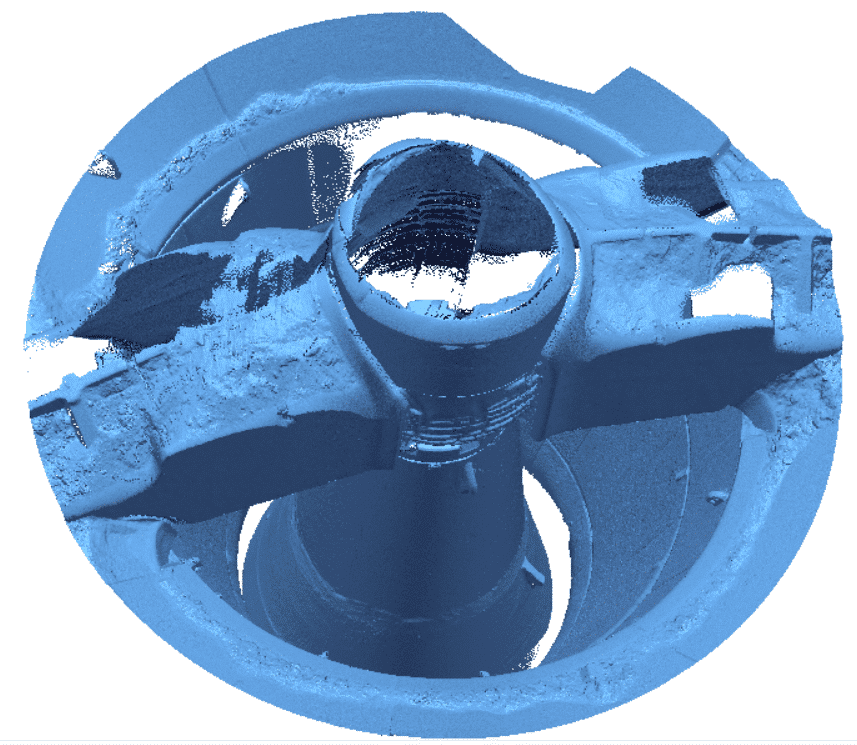

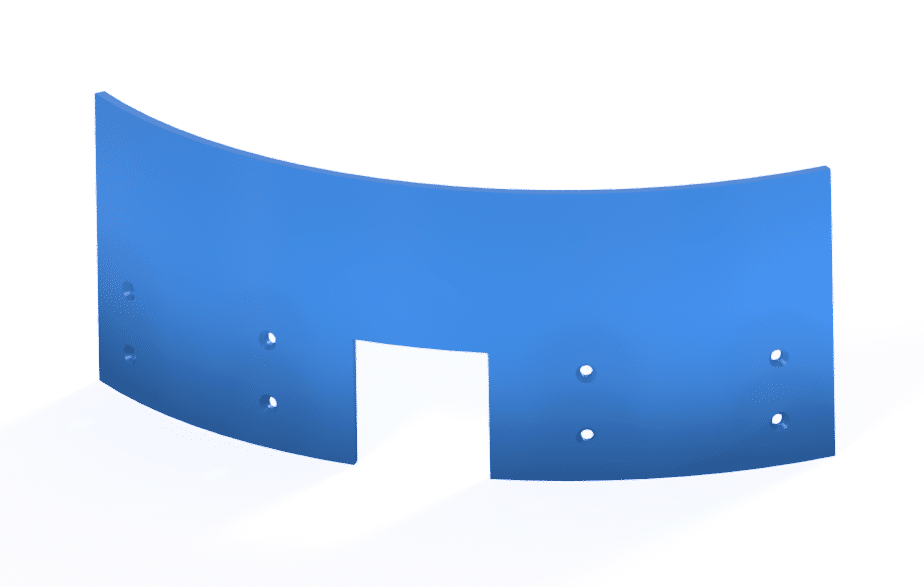

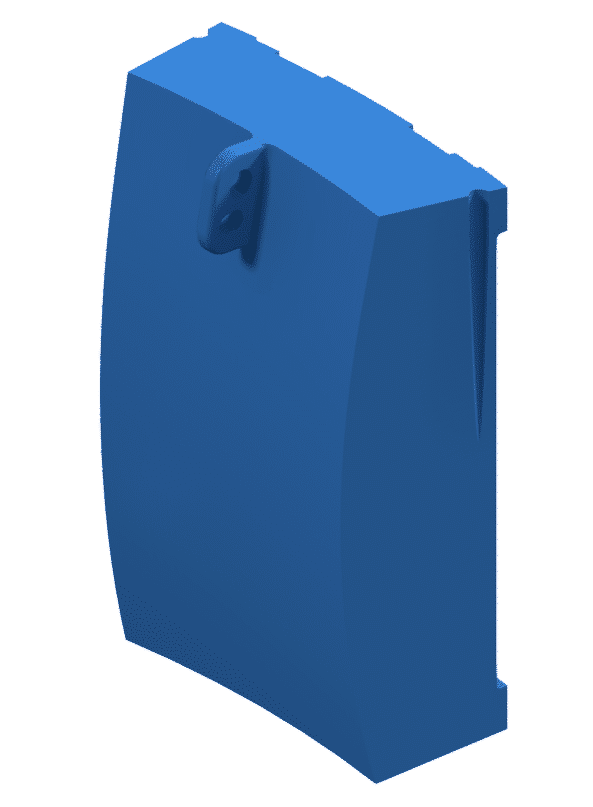

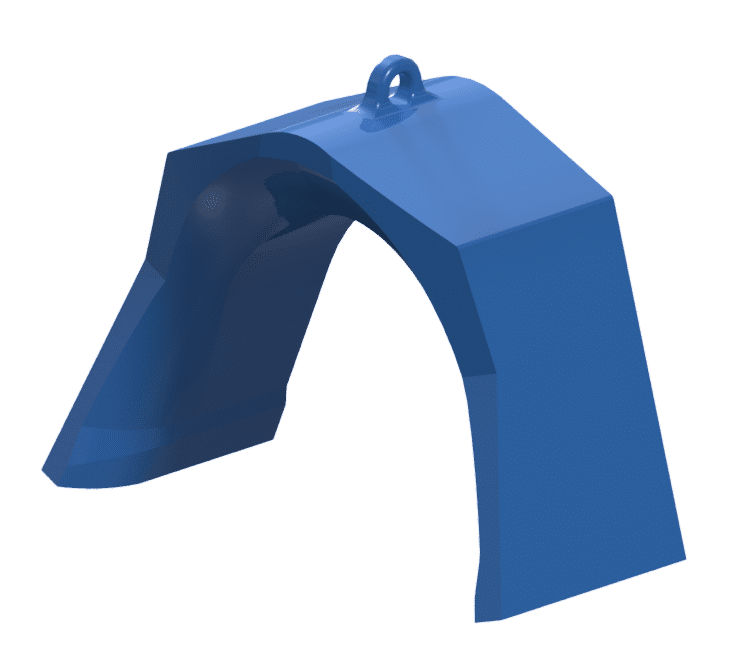

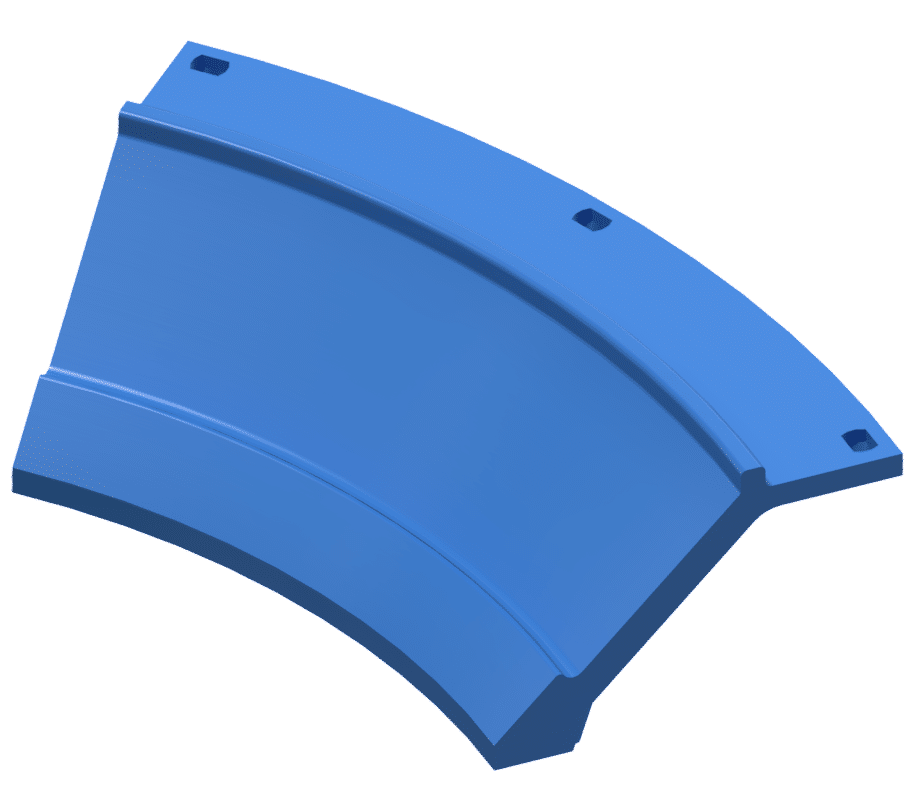

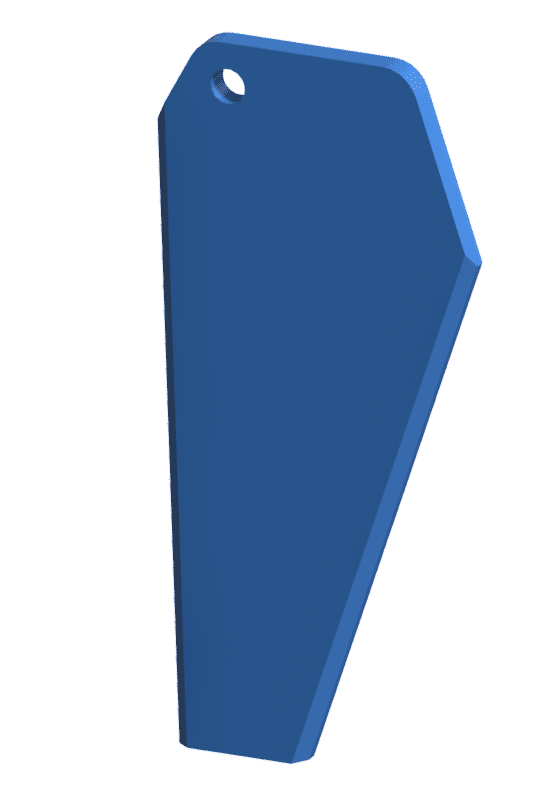

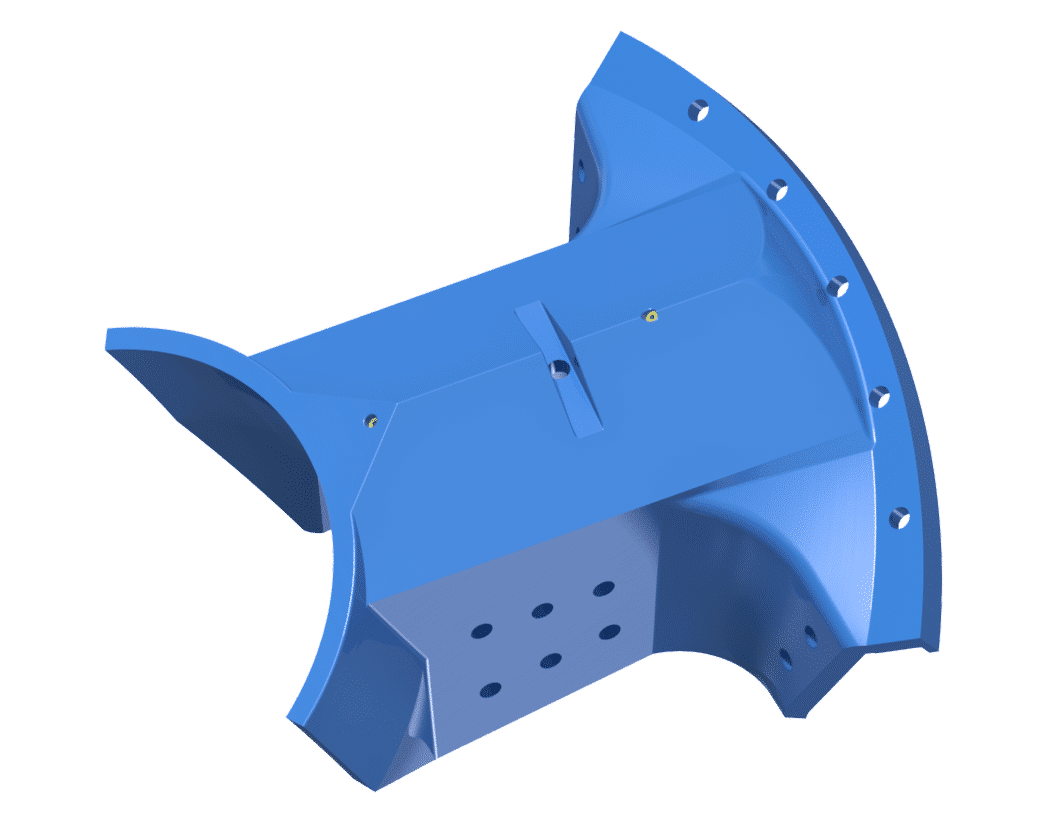

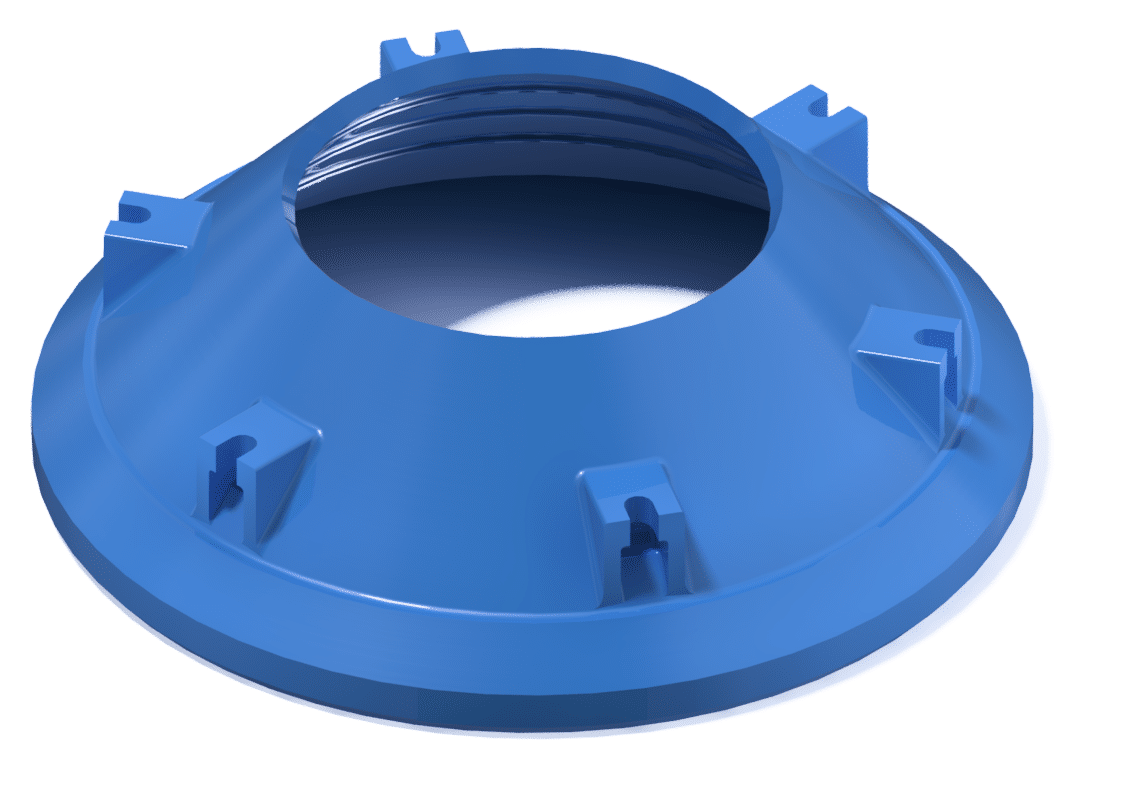

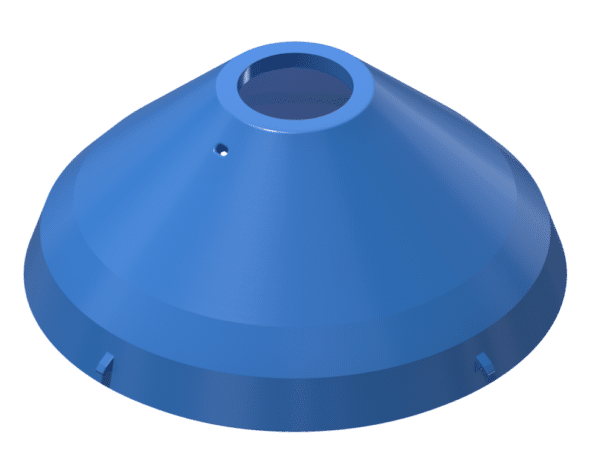

Wear components for crushing processes are subjected to severe impact and high abrasion, requiring solutions made from high-strength and abrasion-resistant alloys. ME Elecmetal is the leader in offering wear solutions to crusher operators. We provide wear parts for primary, secondary and tertiary crushing applications for the mining, aggregate and recycle industries with optimal designs and alloys specifically developed for each application. We will help tackle any customer challenge, while striving to maximize the benefits we provide.

Because we use top-quality wear materials our products last longer, thereby extending the service life of each product.

Because our products have a longer service life, they require less frequent preventive maintenance, which in turn frees up more time for production.

Our crusher products are designed to be replaced as quickly as possible in order to keep down times to a minimum.

Our technology and designs are instrumental in enabling us to anticipate possible component failures or wear so that we can notify our customers in time to make changes that will prevent unscheduled downtime.