Longer service life

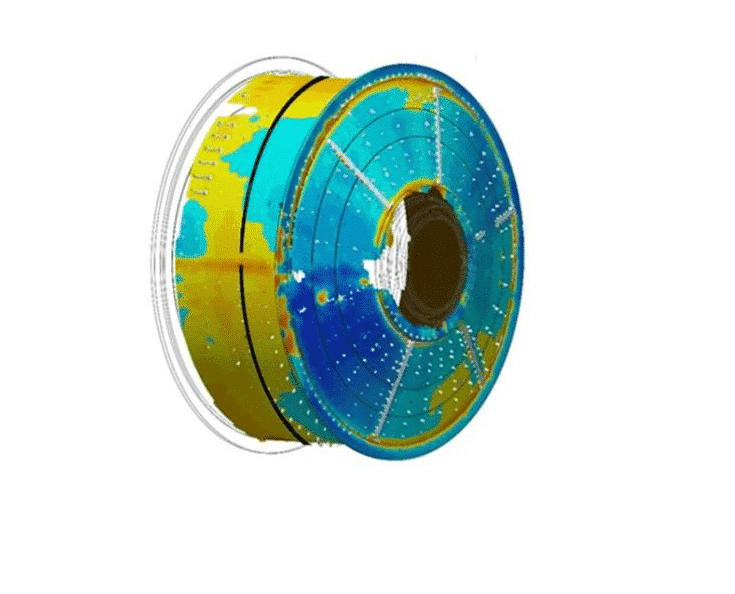

Our state-of-the-art facilities use the highest quality raw materials and high-end heat treatment technology based on our decades of metallurgical experience, providing a lower wear rate.

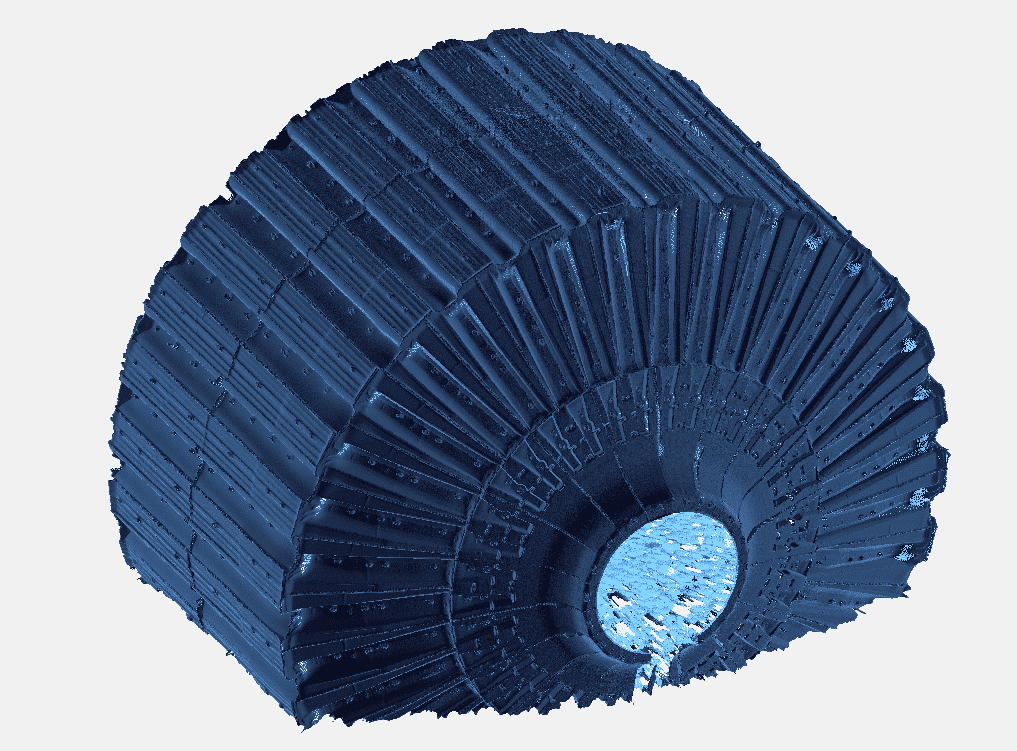

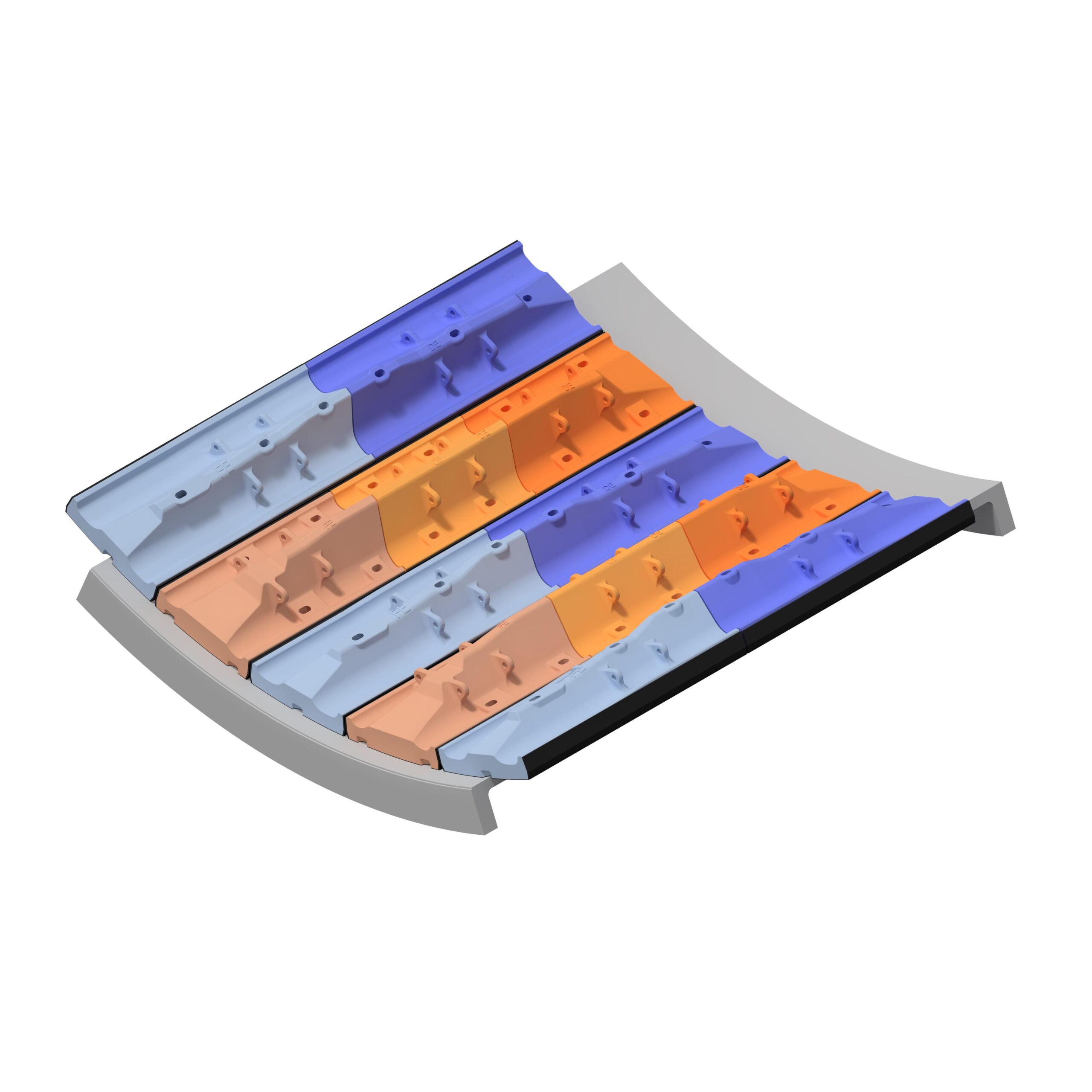

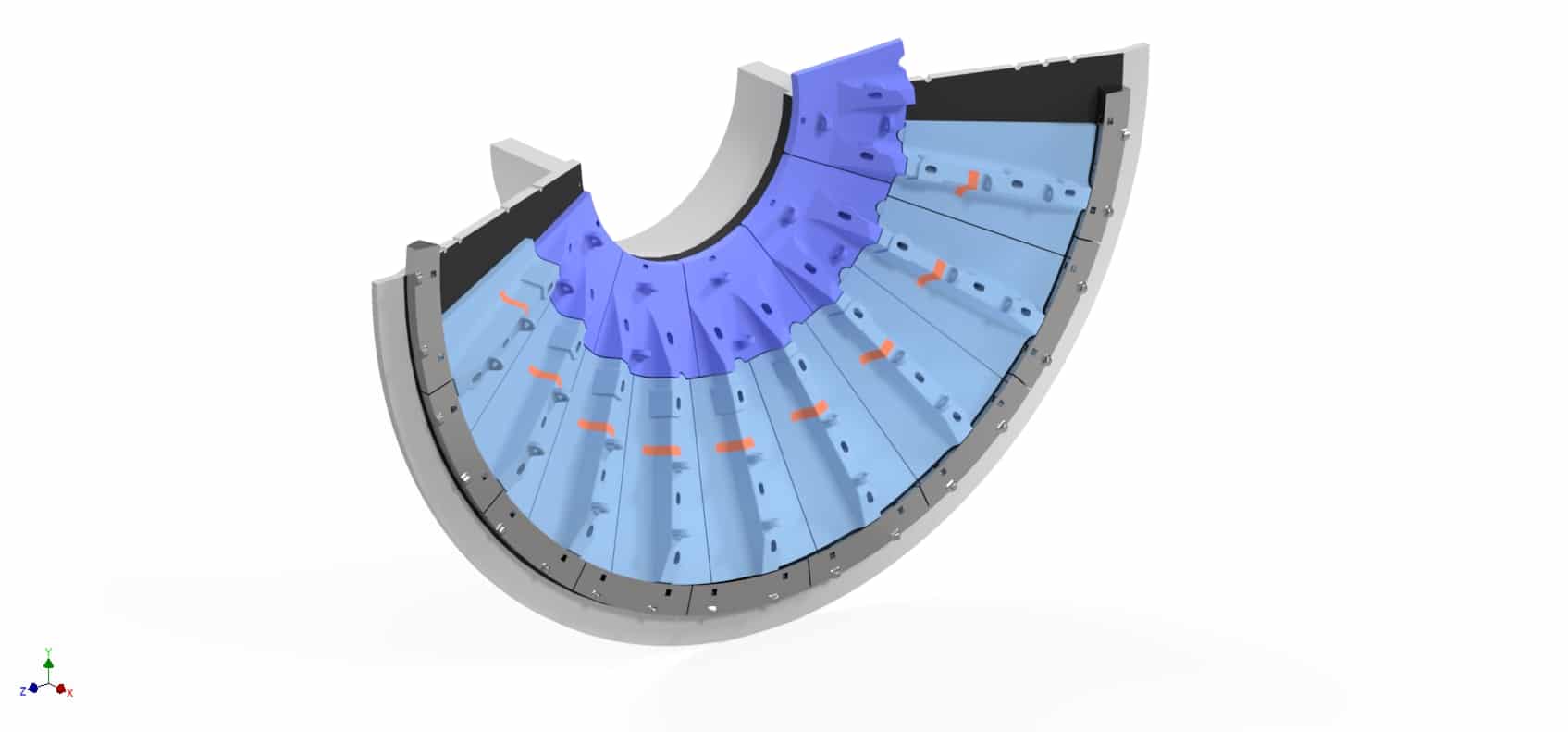

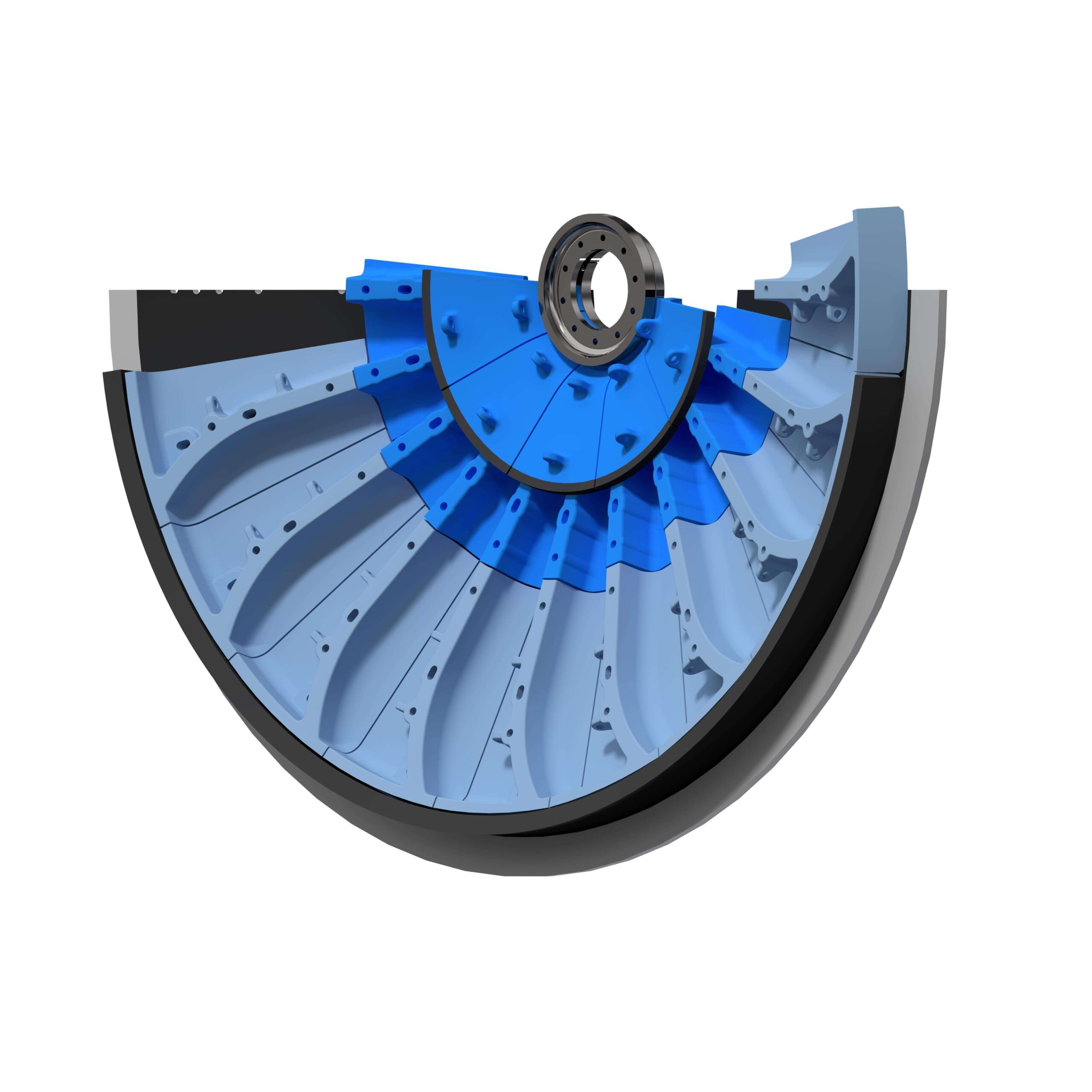

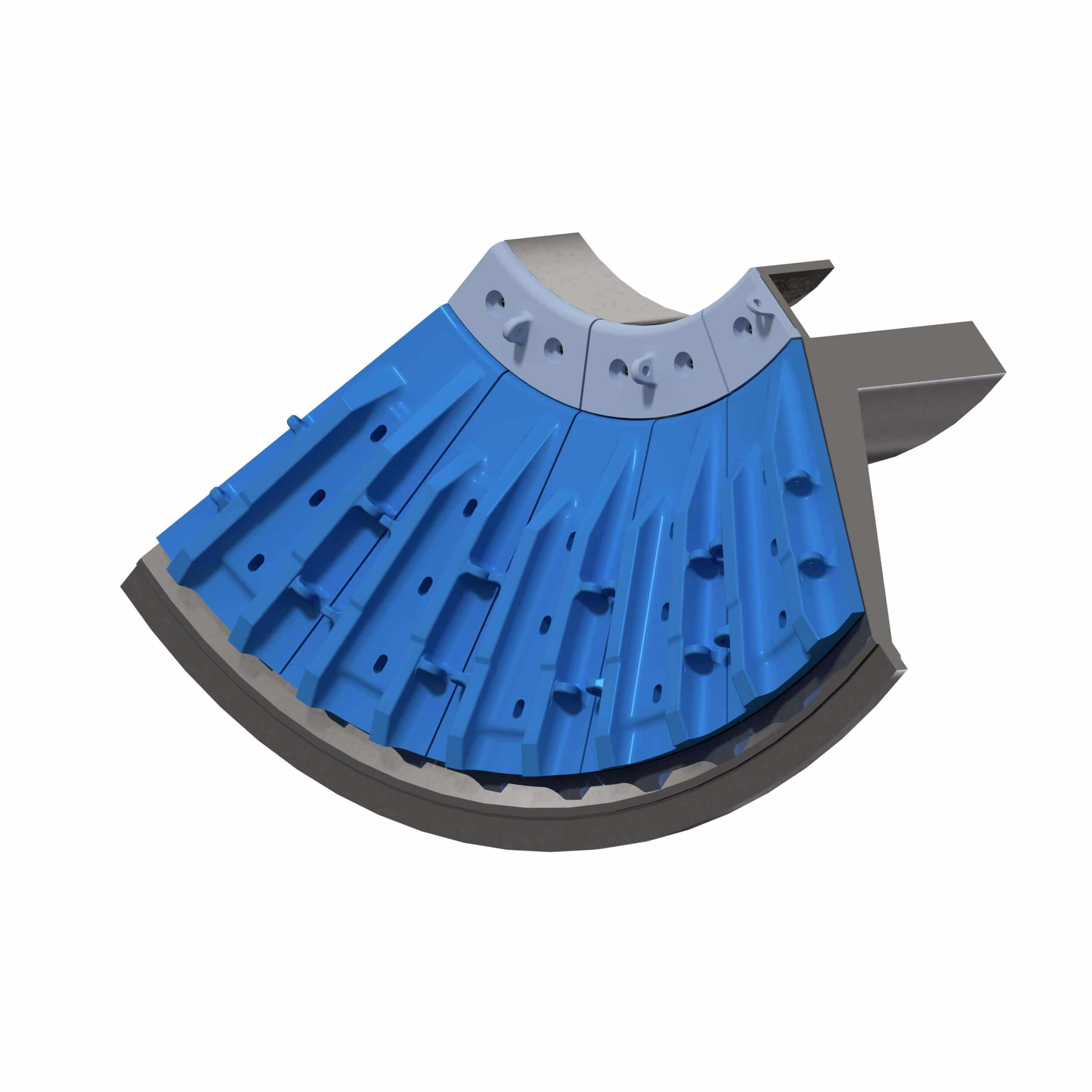

Grinding wear parts are subjected to severe impact and high abrasion. They must be manufactured using the best technologies and designs for superior strength and durability. That is why we make sure we offer customers the best possible solutions for every challenge and mill type.

Our state-of-the-art facilities use the highest quality raw materials and high-end heat treatment technology based on our decades of metallurgical experience, providing a lower wear rate.

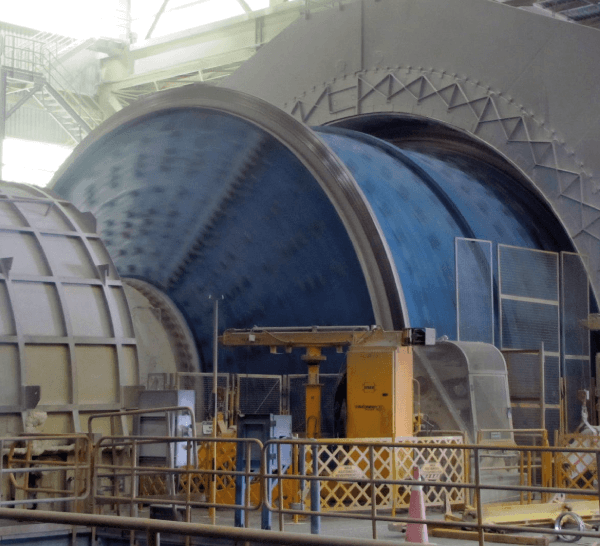

Our products are made to the industry’s highest quality standards, achieving improved uptime and reduced unscheduled maintenance — leading to lower maintenance expenses. Our quality management system is ISO 9001 certified.

Because our products have a longer service life, they require less frequent preventive maintenance, which in turn frees up more time for production.

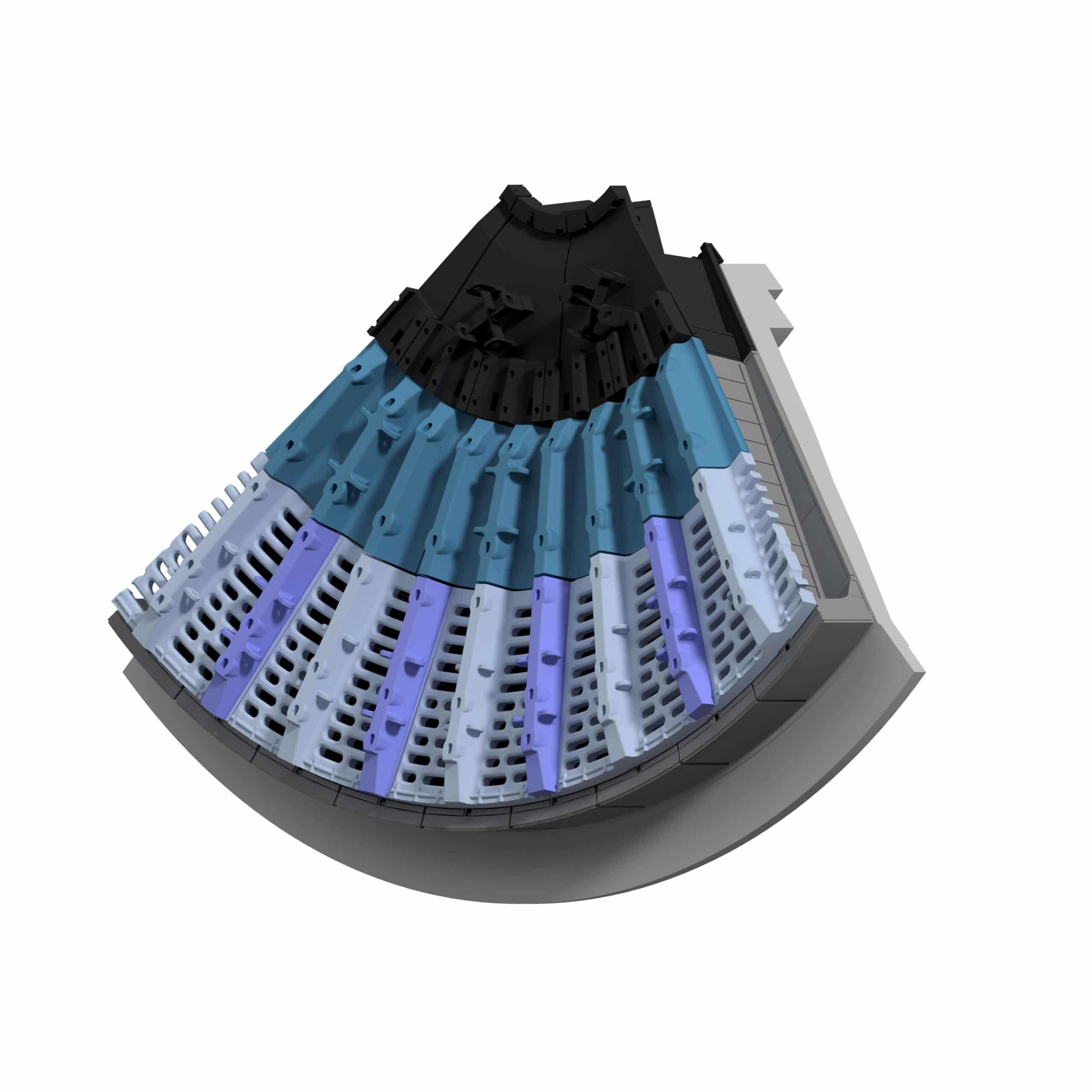

Our technology and designs are instrumental in enabling us to anticipate possible component failures or wear so that we can notify our customers in time to make changes that will prevent unscheduled downtime.