Increased asset availability and reliability

We ensure real-time symptomatic analysis of assets, anticipating possible wear and tear, assessing mechanical and structural integrity, and the life cycle of components and consumables.

Through our asset monitoring, process monitoring and on-site support and assistance solutions, coupled with our vast experience in mining processes, we ensure better performance in these four main areas:

We ensure real-time symptomatic analysis of assets, anticipating possible wear and tear, assessing mechanical and structural integrity, and the life cycle of components and consumables.

We empower our customers with information relevant to them regarding their critical spare parts supply chain, showing in real time the status of their inventories to ensure reliability of your operation.

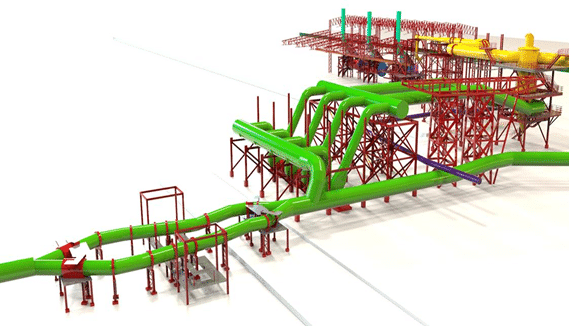

Monitoring of process variables in Mine, Crushing and Grinding, generating analysis and performance predictions of each process to achieve consistent performance and reliability of assets and processes, for the implementation of best practices.

We focus on optimizing the effective operational cost of our clients, optimizing their processes so that they can achieve greater rentability.