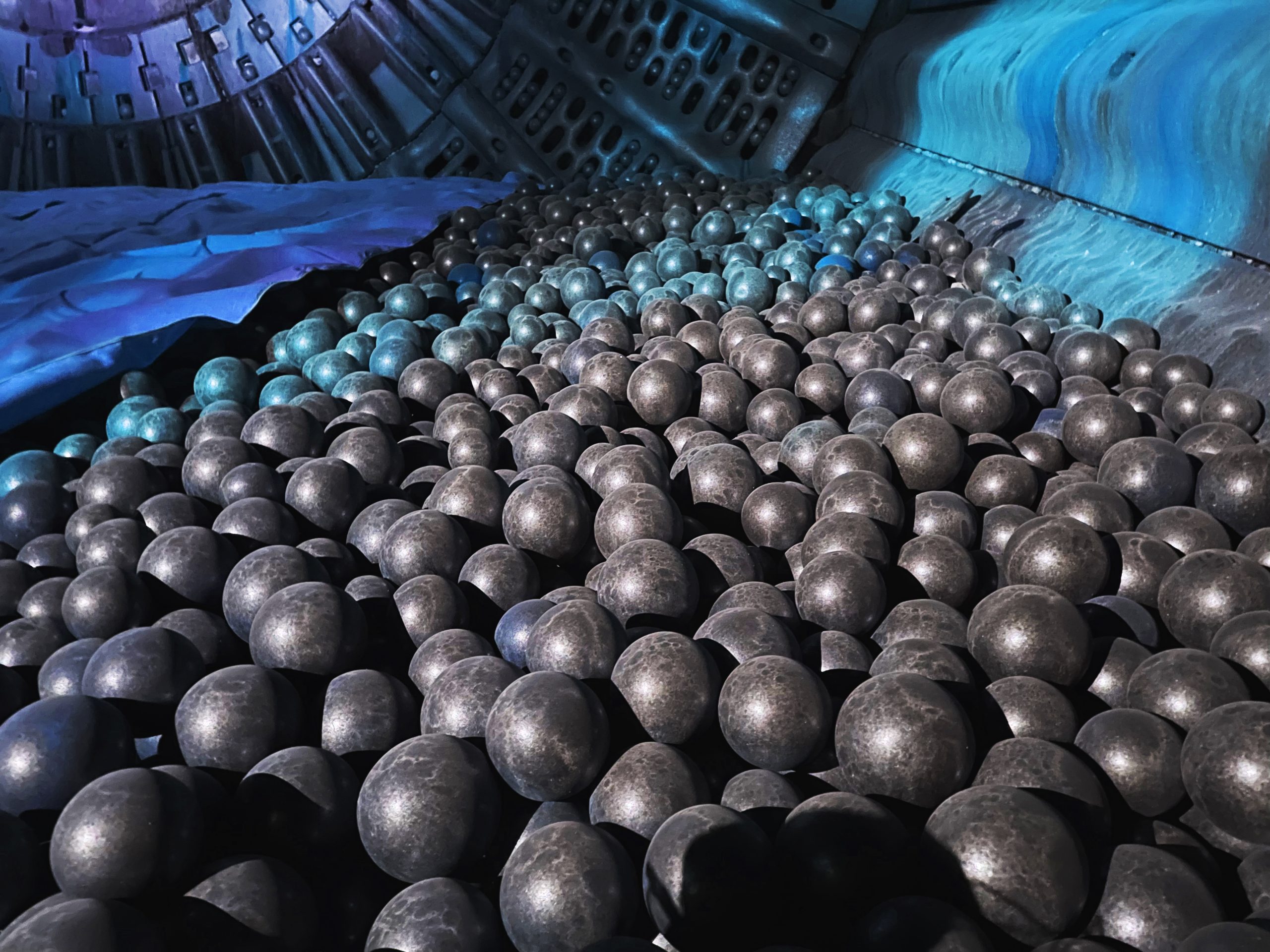

Critical consumables at a lower effective cost

The superior quality and performance of our grinding media enables us to confidently guarantee customers lower effective costs for logistics and media performance.

Our experience and large-scale grinding media production capacity have positioned ME Elecmetal as a strategic partner in the global mining market. Our experienced and knowledgeable sales and application engineers can help you monitor and improve your processes by collecting and analyzing operating data, improving media charging practices and offering solutions to optimize your grinding media consumption and improve throughput.

The superior quality and performance of our grinding media enables us to confidently guarantee customers lower effective costs for logistics and media performance.

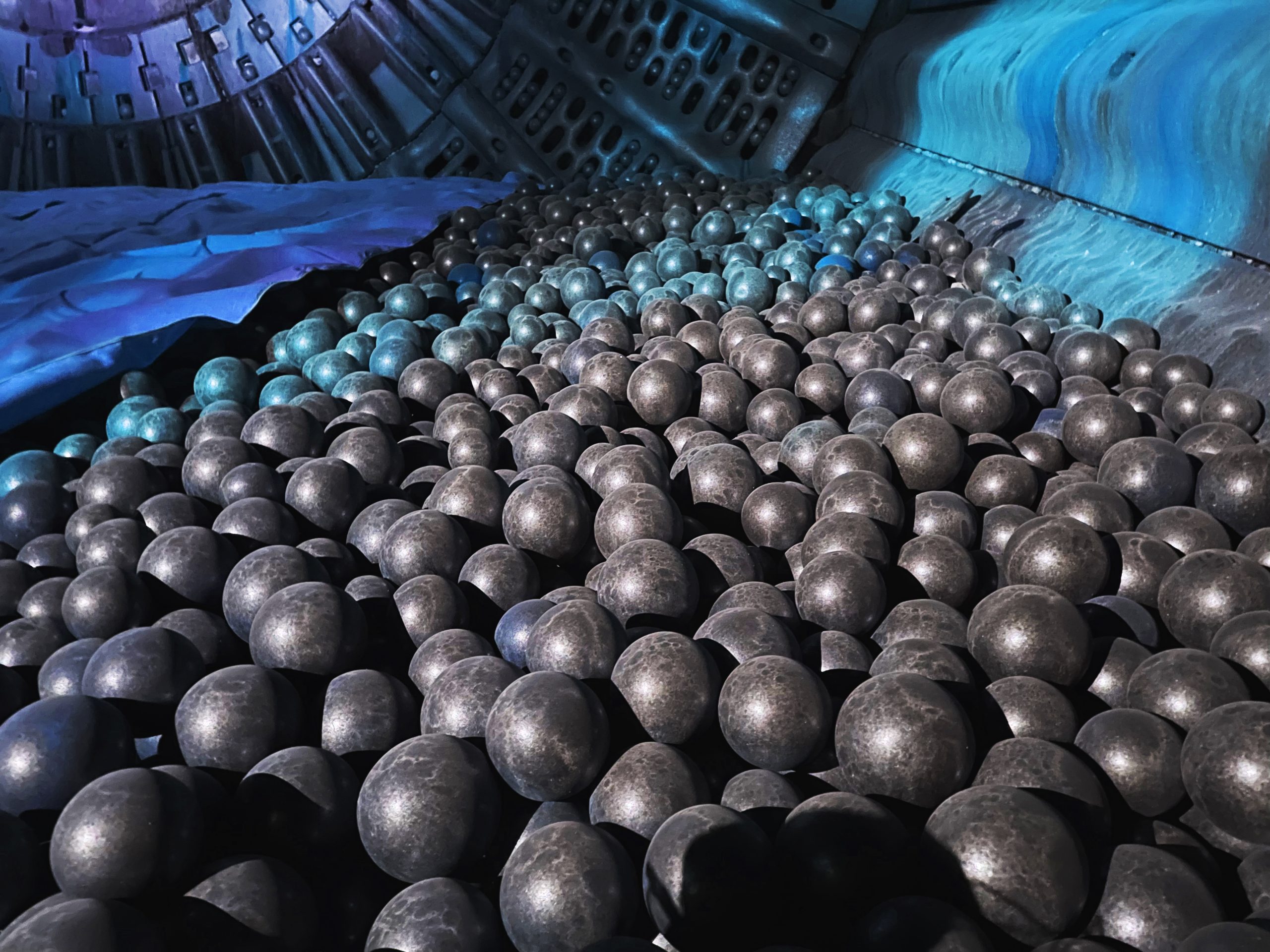

Because our grinding media has a lower wear rate, it lasts longer. This allows customers to decrease the number of trucks traveling to and from the mine site, enabling them to reduce their carbon footprint and the risks associated with transportation.

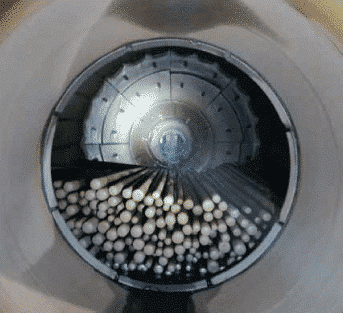

ME Elecmetal carries a wide range of ball products to suit customer grinding applications and operational requirements.

Our large-scale global production capacity makes ME Elecmetal a reliable and consistent quality supplier.