Advancing Circularity Through Strategic Measurement and Action

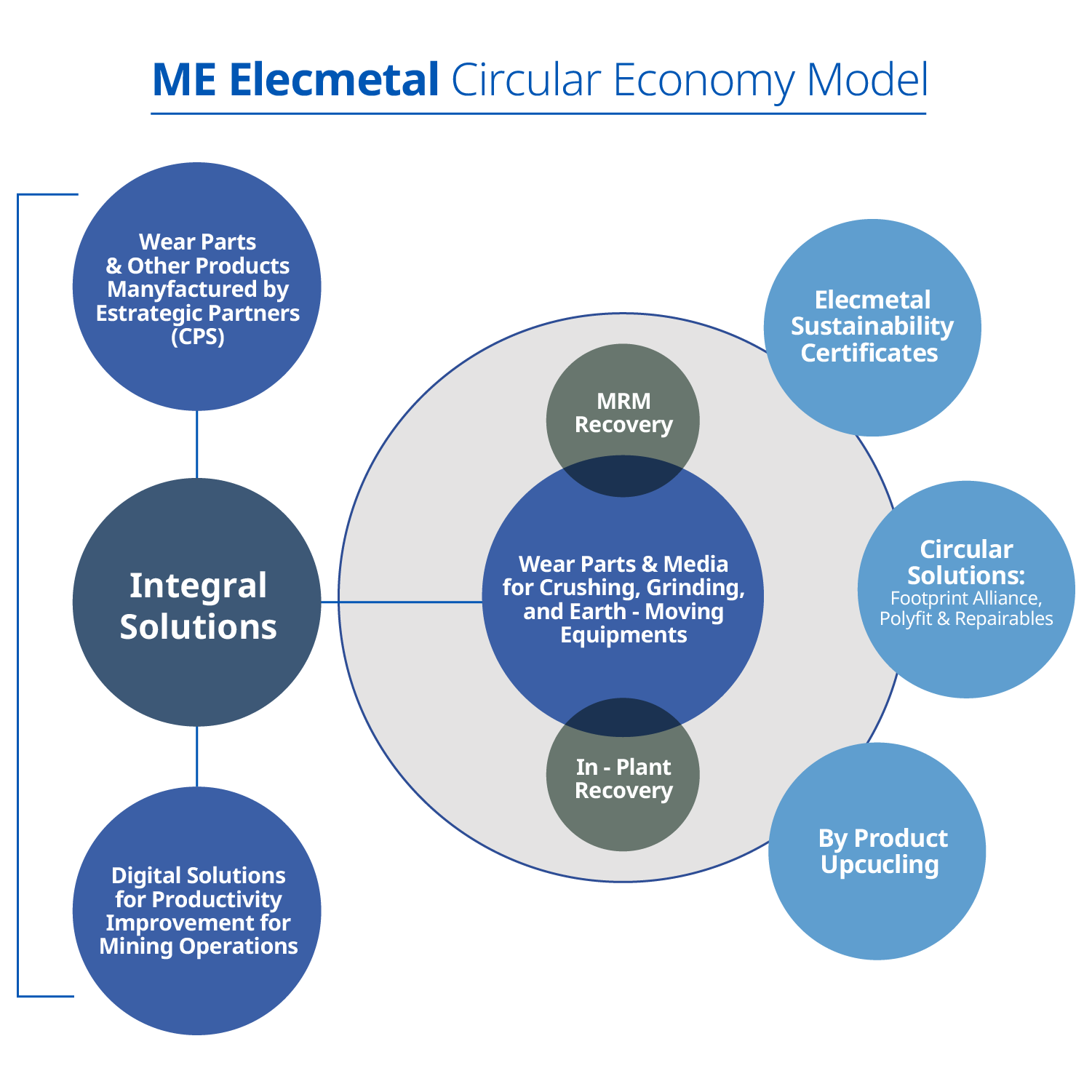

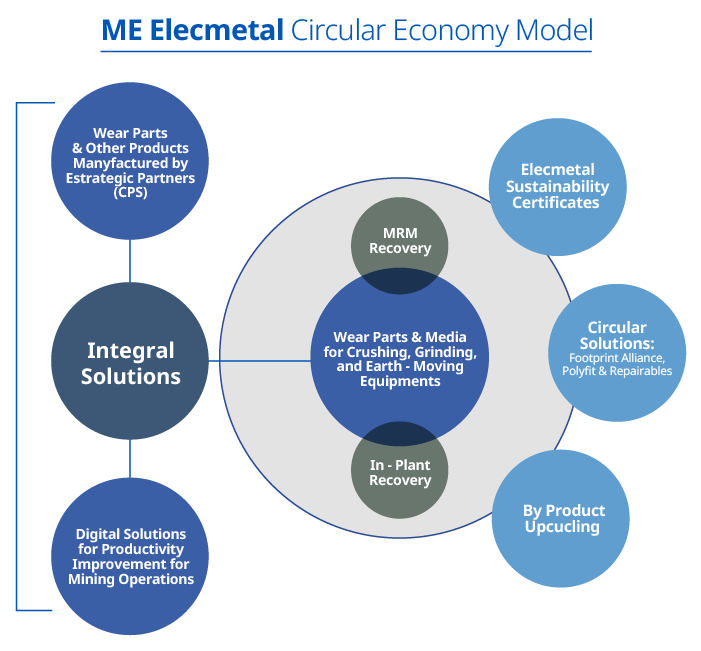

In line with ME Elecmetal’s global circular economy strategy, the 2024 initiative led to the development of a comprehensive Circularity Flow and a global Circularity Map for all ME Elecmetal foundries. In Chile, these efforts were formalized through participation in the Clean Production Agreement (APL), with the goal of improving operational efficiency at the Rancagua Plant. This was achieved using the Circular Transition Indicators (CTI) methodology developed by the World Business Council for Sustainable Development (WBCSD), resulting in a baseline circularity indicator of 83%.

As part of the APL, a Circularity Baseline was established using an international methodology created by the Ellen MacArthur Foundation and implemented through WBCSD and its Chilean partner, Acción Empresas. To support implementation, ME Elecmetal conducted extensive circular economy training—reaching 300 employees through 16 dedicated courses. These trainings enabled tangible improvements, including increased reintegration of by-products into production and a significant reduction in waste previously sent to landfills.

To further guide the transition, ME Elecmetal leveraged the Circular Transition Indicators Guide 2.0, developed by WBCSD and KPMG. This tool enabled the Rancagua Plant to assess and benchmark its circularity performance. Additionally, ME Elecmetal adopted the Practical Guide for the Selection of Circular Suppliers, providing its teams with a structured framework to evaluate supply chain partners based on their alignment with circular economy principles.

Achieving the 83% circularity indicator was the result of a detailed identification and classification of all process by-products by volume. This analysis informed the development of short-, medium-, and long-term action plans to reduce and manage these materials more efficiently. The entire process was subject to rigorous auditing—from waste generation data collection and condition verification to outcome measurement and continuous improvement planning.